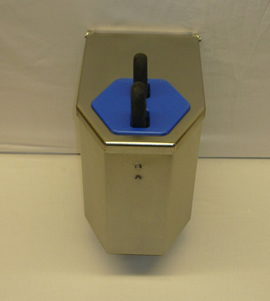

The ECONOLISER is the worlds' first twin knife steriliser that has been designed from the ground up to efficiently sterilise the knives used in abattoir, slaughter halls, meat plants, butchers etc but at the same time use the absolute minimum amount of 82 deg C water. British Patent Pending.

Each sterilising cycle uses between 60cc's to 180cc's of hot water depending on local regulations which means a massive saving in both water consumption and the treatment of it before it leaves the plant, but more importantly, a huge saving in the cost of the energy to heat the water

eg ann abbatoir killing 300 animals per 8hr day equipped with 55 constant feed type sterilisers could use as much as 75cu metres of hot water per day. Upgrading to the Econolisers could reduce the consumption to as little as 2.5 cubic metres or even less per day. Thats a saving of 96%!

Many of the Econolisers competitors leave the knife stewing in a hot soup of waste matter which coats the blade every time it is removed. Not the Econoliser! Every sterilising cycle uses only fresh hot water and all waste is carried to drain by the end of the cycle. Recent swab tests have shown that the knives sterilised in the Econoliser come out much cleaner than from other systems. These tests were conducted by abbatoirs themselves.

Because they use so little water, steam and therefore condensation on the meat is virtually eliminated.

The ECONOLISER has been designed for ease of maintenance, with all parts being easily replaced.

They are made of 304 grade 1.5mm Stainless steel, laser cut to 0.5mm accuracy and then CNC folded and finally jig welded, this ensures interchangeability of parts. Parts bought in for the controls are from Norgren, Buschjost, and Creuzet. These are all European manufacturers which were chosen for their excellent reputations for reliability and availability of spares.

They can be tilted forward slightly when installing them making it easier for the operator to insert and remove the knives.

If you are interested in knowing more about the ECONOLISER or if you would like to know how much your existing sterilisers are costing and how much you could save by switching to the ECONOLISERS please email us with the following information and we will contact you with the results.

1) No of Knife Sterilisers in daily use

2) Average No of animals killed per day

3) How many Cu Metres of water is used by the existing knife sterilisers on average each day (phone us for assistance in calculating this)

4) Cost per Kilowatt/hr

5) Temperature of your rising main water (Approx)

Airtech exporting to Australian beef producer:

http://www.investni.com/news/airtech-wins-first-export-to-australia-for-innovative-technology.html

Airtech featured in the Belfast Telegraph newspaper:

Airtech featured in MeatInfo.co.uk:

Our export activities featured in Globalmeatnews.com: